Luping

Junior Member

Hallo

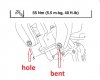

I had a crash at 40 km/h. I broke my collar bone, handlebar was a little bit bent (5mm) and right crash pad destroyed. I changed both crash pads and handlebar with new one but after 6000 rpm i have a strange vibration in foot pags and handlebar, looks like a resonance.

Anyone have any ideas ?

Thank you

I had a crash at 40 km/h. I broke my collar bone, handlebar was a little bit bent (5mm) and right crash pad destroyed. I changed both crash pads and handlebar with new one but after 6000 rpm i have a strange vibration in foot pags and handlebar, looks like a resonance.

Anyone have any ideas ?

Thank you