Project outline: determine Ignition Advance rate of Stock 2008 FZ6

Goal:

Plot graph from idle to redline of ignition advance/spark advance while changing variables. Questions are many! Like; What effects advance, how much does it have, what can I gain by changing it.. .. ..

At minimum I expect the RPM, TPS, and maybe the gear selected to be variables. Others could include Engine temperature, Engine Vacuum, and O2 output (highly unlikely), airbox temp (also HU).

How will I figure it out:

Using the bike under load is not an option as that involves holding a timing light to its internals while going down the road reading a degree wheel with oil flying out og the crankcase. Not gonna happen. Next option is to fake the ECU into thinking the bike is running. That is doable!

With an RC speed controller and brushless motor I intend to spin a spare trigger wheel up through a range of RPMs while a spare CKP sensor monitors its output sending it to the ECU. Now compare the rpm vs timing advance delivered to the spark plugs using an oscilloscope. The waste spark system will complicate this, but I'll figure that out.

Issue to overcome:

1) I need an electronic transmission as the crank on the bike won't be turning but the ECM will see a crank input signal. I can verify my tach and motor speed calculations so I have two reference points in that area. I need to make a circuit with a divider, an amplifier, and out output that has selection to mimic what the transmission gear ratios do (an electronic divider circuit that matches the ratios of the transmission) and feed that to the ECU. So I need mimic the transmissions output sensor.

2) Simulate TPS = easy, turn the grip

3) simulate Engine Temp = easy, a variable resistor

4) simulate Engine vacuum = easy, a syringe to the sensor with a gauge to monitor pressure.

5) O2 sensor, I doubt it looks at this, but I need to consider it might expect a signal. If so another simulator to make. A signusoidal wave floating on a DC signal. ~ possible ~

WHY WOULD I DO THIS?? lol

Well, I modified an OEM trigger wheel advancing the static timing about 5 degrees! The engine WAKES UP! It becomes VERY responsive to throttle input, it runs smoother, pulls harder and makes me grin more.

Main reason; I really want to know if the advance curve cares what gear the bike is in. If it changes the curve based upon "what gear is selected" It could really come alive a rumor has it, 1,2,3 offer limited advance. Also the R6 runs about 5+ degrees more advance than our engine.

If I find it has limited advance, I may ship off othe ECM to ECU Unleashed who I might add, does to Group Buys of ECU re-map.... Still not cheap tho.

Meet Trigger:

Trigger, test drive #1:

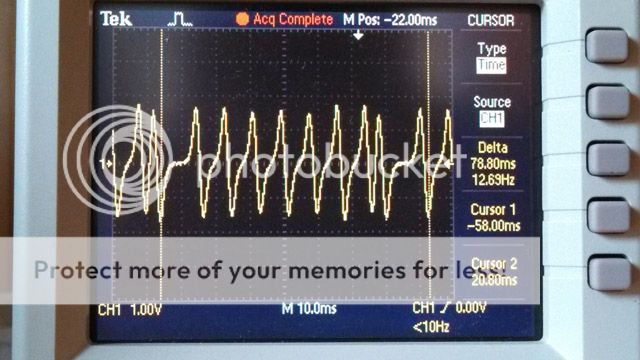

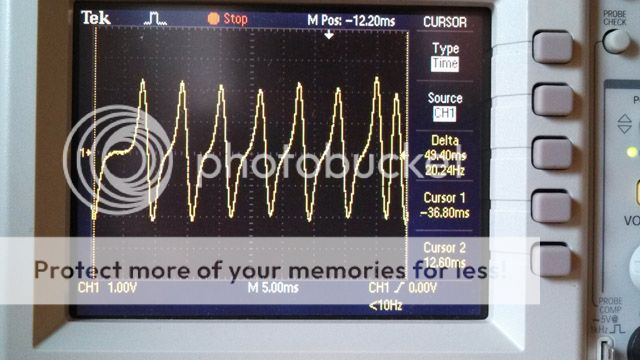

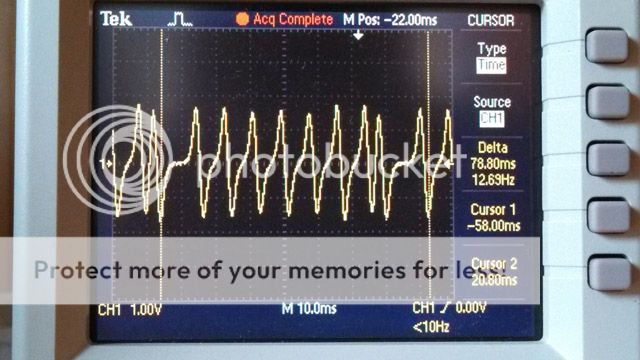

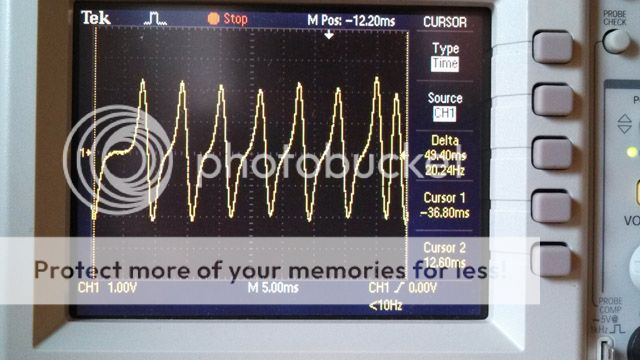

Trigger at 1214 RPM: hint - my idle speed is roughly 1200 RPM so this is a good baseline to work from.

RPM = t/period or 60sec/0.0494sec = 1214 RPM

Trigger plus Dewalt: lol

Its going to make countless MIL codes to the display, but I don't care. I'll have the fuel pump disconnected but let the plugs and injectors fire. Injectors MAY get unlpugged as I I suppose this could heat them with no fuel to cool them. IDK

That's it for now. oh - you'll notice the trigger wheel is not symmetrical. The camel hump next to each other creates the variation shown on the O'scope. It locates number one. I'd like to make an electronic filter to detect it. So I have some reading to do unless someone knows how to extract that signature from the signal!

Also - thanks Skooter!!! :thumbup:

Goal:

Plot graph from idle to redline of ignition advance/spark advance while changing variables. Questions are many! Like; What effects advance, how much does it have, what can I gain by changing it.. .. ..

At minimum I expect the RPM, TPS, and maybe the gear selected to be variables. Others could include Engine temperature, Engine Vacuum, and O2 output (highly unlikely), airbox temp (also HU).

How will I figure it out:

Using the bike under load is not an option as that involves holding a timing light to its internals while going down the road reading a degree wheel with oil flying out og the crankcase. Not gonna happen. Next option is to fake the ECU into thinking the bike is running. That is doable!

With an RC speed controller and brushless motor I intend to spin a spare trigger wheel up through a range of RPMs while a spare CKP sensor monitors its output sending it to the ECU. Now compare the rpm vs timing advance delivered to the spark plugs using an oscilloscope. The waste spark system will complicate this, but I'll figure that out.

Issue to overcome:

1) I need an electronic transmission as the crank on the bike won't be turning but the ECM will see a crank input signal. I can verify my tach and motor speed calculations so I have two reference points in that area. I need to make a circuit with a divider, an amplifier, and out output that has selection to mimic what the transmission gear ratios do (an electronic divider circuit that matches the ratios of the transmission) and feed that to the ECU. So I need mimic the transmissions output sensor.

2) Simulate TPS = easy, turn the grip

3) simulate Engine Temp = easy, a variable resistor

4) simulate Engine vacuum = easy, a syringe to the sensor with a gauge to monitor pressure.

5) O2 sensor, I doubt it looks at this, but I need to consider it might expect a signal. If so another simulator to make. A signusoidal wave floating on a DC signal. ~ possible ~

WHY WOULD I DO THIS?? lol

Well, I modified an OEM trigger wheel advancing the static timing about 5 degrees! The engine WAKES UP! It becomes VERY responsive to throttle input, it runs smoother, pulls harder and makes me grin more.

Main reason; I really want to know if the advance curve cares what gear the bike is in. If it changes the curve based upon "what gear is selected" It could really come alive a rumor has it, 1,2,3 offer limited advance. Also the R6 runs about 5+ degrees more advance than our engine.

If I find it has limited advance, I may ship off othe ECM to ECU Unleashed who I might add, does to Group Buys of ECU re-map.... Still not cheap tho.

Meet Trigger:

Trigger, test drive #1:

Trigger at 1214 RPM: hint - my idle speed is roughly 1200 RPM so this is a good baseline to work from.

RPM = t/period or 60sec/0.0494sec = 1214 RPM

Trigger plus Dewalt: lol

Its going to make countless MIL codes to the display, but I don't care. I'll have the fuel pump disconnected but let the plugs and injectors fire. Injectors MAY get unlpugged as I I suppose this could heat them with no fuel to cool them. IDK

That's it for now. oh - you'll notice the trigger wheel is not symmetrical. The camel hump next to each other creates the variation shown on the O'scope. It locates number one. I'd like to make an electronic filter to detect it. So I have some reading to do unless someone knows how to extract that signature from the signal!

Also - thanks Skooter!!! :thumbup:

Last edited by a moderator: